Lakda Udyog Darshan, October 2011, India.

‘WPC boards’ – a fastest running product for Indian, Arab and African Infrastructure markets

– By Hardik Panchal, Hardy Smith, India (info@hardysmith.org)

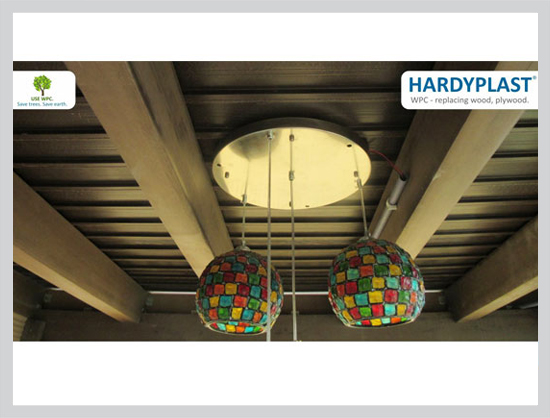

Changing product trend as per the cyclic process of product life cycle, WPC boards are replacing shuttering ply boards with its enduring and highly competitive properties. WPC stands for wood plastic composite and this is a unique and evolutionary product derived from a non conventional extrusion process for wood panel industry which has been using pressing technology. As a fortune product for Indian interior and infrastructure industry which is just enjoying its childhood yet in compare to the other developed countries.

WPC boards are available with various names like ‘Construction boards’, ‘Crust foam boards’, ‘Calcium boards’, ‘WPC shuttering boards’ ‘WPC MDF boards’ in global markets. WPC boards can be produced with flexible density range varies from 400 kg/cum to 900 kg/cum. Another important characteristic is the surface density of this product and which also can be adjusted between a range of 55 shore D to 85 shore D surface hardness.

Formulations play a major role in making WPC boards and that is the master key which allows it to be known by different names as above. Wood wastes, Virgin and recycled plastics are key components for making these composite boards. These boards are covering a large application area starting from interior grade boards being used for making furniture, kitchen cabinets, kitchen shutters. Taking further, these boards are being used for making temporary shelters for government housing projects, construction site pavilions/shelters, low cost housing projects and other road and building projects.

The high end application of these boards are fall under the category name of ‘Construction boards’, those are effectively being used as a master replacement of ‘Shuttering ply’ and ‘metal templates’. This board can be used more than 20 times in compare to the conventional shuttering ply used for 4-5 times only. Handling, storage and life are key competitive factors above its all other advantages including moisture repellence, non-deformity in shapes and layers, easy to cut, light in weight.

For further information about technology and projects for WPC boards you can write to info@hardysmith.org or visit www.hardysmith.org.