PLY REPORTER Magazine, January 2016, India.

Q. What would be the new products at your stall?

A: We shall demonstrate wood polymer composite technology and products (both) during this exhibition. We are going to launch ‘A purchase guide for WPC’ during this exhibition.

Q. How do you establish that WPC is an alternate of Plywood?

A: WPC has following specialties to replace plywood:

1. Good screw holding for furniture making (holes can be refilled easily with same material & solvent for life long sustainability)

2. Good Dimensional stability for structural applications

3. Good machinability for wood working and panel processing,

4. Water resistant and termite/borer resistant

5. Outstanding surface finish for direct applications in furniture and partitioning

Q. Besides Water resistance and Anti Termite properties, what are other advantage of WPC/PVC boards?

A:

1. Adhesive friendly and works well with self-adhesive tapes for HPL, Stainless Steel plates, Acrylic

2. Printability on surface for Direct Digital printing & roller printing possible,

3. Direct use of WPC panels for carcass/storage building without HPL or Paint or coating,

4. Light weight construction possible & best for green buildings

5. 100% recyclable nature and can be reused the material at any future date

6. Value for money and assures 20% money back (as scrap even) at any future date

7. Fastest material ever for furniture making with solvent joinery

8. Can be 90 degree bent with ‘V’ grooving technique for door making

9. WPC Thicker sheets can be directly used as Solid Door that replaces solid wooden door & ply doors

10. Best product for CNC routing and serving to a huge interior and exterior Grill board market, replaces MDF & Wood

11. No headache for putting filling and painting for end use, it’s plug and play material

Q. Strength of Board is directly related to Density, but WPC/PVC boards carry very low density, hence how do you compare these boards with Plywood?

A: Only Density doesn’t play a role in this new era. Property of a material also carries a lot of importance. Usually density remains in discussion with its relation to screw holding capacity of a materials. But WPC PVC boards holds screws nicely with having moderate density (not low density). You can get this boards with even 900 Kg/cum also. Most importantly, No screw furniture is an upcoming trend with this materials. WPVC boards are capturing furniture markets with its most effective joinery technique with solvent cements/cyanoacrylate adhesives. Furniture units are being made without screw with WPVC board & such adhesives. This mechanism works so precisely that a 15 ft long wardrobe build up with Cyanoacrylate & WPVC boards becomes one unit with several joints. It keeps standing with superb dimensional stability and no warpage. Small units like storage boxes, side trolleys, book shelves, office table units etc can be built in couple of minutes, just without screw.

Q. Who are your target visitors (Dealers/Architects/Furniture makers) at Indiawood?

A: As a Project & machinery player we look forward for investors from wood, plywood & plastic industry as visitors. As WPC CENTRE we look forward for Dealers, Architects, Interiors & Furniture makers as our target visitors.

Q. What is your expectation from visitors of Indiawood?

A: We forecast this exhibition to be benchmark for WPC industry in terms of number of visitors. Visitors will surely gain more information and knowledge for WPC products and industry as a whole during this Indiawood show. We look forward for more projects and more channel partners.

Q. How do you expect India’s WPC/PVC demand growth this year?

A: This year will be a benchmark year for WPC industry and targeted growth is 25-30%. Being added with more potential players from the industry, WPC PVC will fetch more awareness, demand and consumption too. This year we forecast for a TV advertisement from WPC players. Lot of happenings are expected with increasing demand.

Q. Brief about your company?

A: We work for wood plastic composites only.

Technology division: We take up turnkey projects under HARDY SMITH firm, where we help entrepreneurs establish WPC manufacturing facilities from concept to commissioning. Our scope of business includes Machines, formulations, and production and application know-how.

Product division: As WPC CENTRE we manufacture and supply WPC boards, WPC Doors, WPC Door frames, WPC Decking & WPC wall cladding under HARDYPLAST brand. We take up turnkey projects with architects for supplying modular furniture for farm houses and village sites of Gujarat.

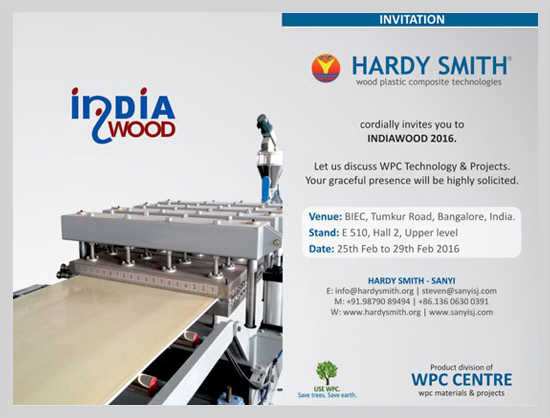

Q. Please also mention your stall number and Managing Director pics

A: Stall number “H2 UL E510”. Please find attached image fyi.