Researchers at VTT Technical Research Centre of Finland have developed a kitchen furniture framework material from plastic polymers reinforced with natural fibre.

It is claimed that the new material, a possible alternative to chipboard, reduces raw material consumption by 25–30 per cent and the carbon footprint of production by 35–45 per cent. Continue reading “Researchers develop composite kitchen framework material”

Resins & Natural fibers for WPC

RESINS FOR WPC

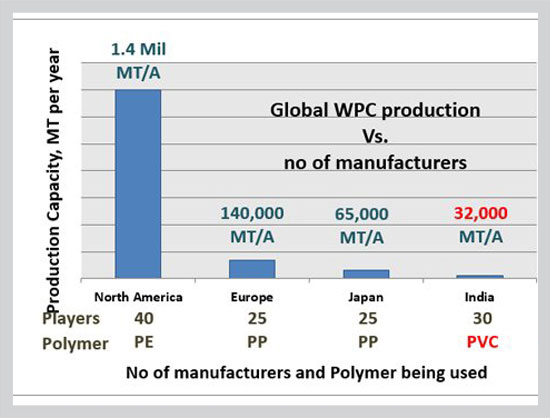

Popular polymer resins for WPC are PVC (Polyvinyl chloride), PE (Polyethylene) and PP (Polypropylene). Globally PE and PP based wood polymer composites are widely used. Indian has started with PVC based WPC board manufacturing in last years. Continue reading “Resins & Natural fibers for WPC”

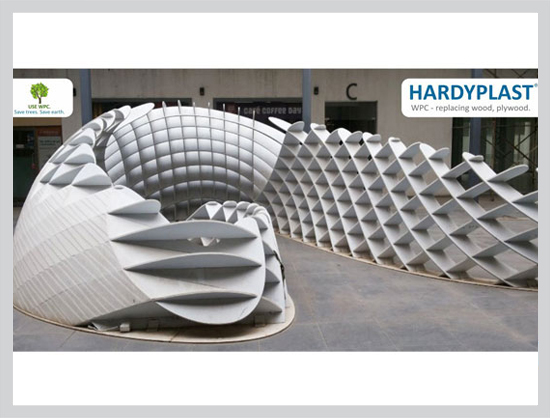

Scupltures & Murals from WPC Boards

WPC sheets can be used for architectural sculptures and murals. Previously we understood about the application of sheets for heritage design preservations. Moving further towards sculptures and murals architects can create unique formations from WPC boards because of its precision for CNC cutting. WPC boards carry outstanding properties for use if outdoor weather applications as shown in the picture. Continue reading “Scupltures & Murals from WPC Boards”

Sonae enters Wood polymer composites

Published: 15 August, 2011

Panel producer Sonae is diversifying into the wood-plastic composites industry after signing a licensing deal to commercialise new technology in Europe. Continue reading “Sonae enters Wood polymer composites”

Technology Partnering with battenfeld cincinnati, austria

Technology Partner

Battenfeld-cincinnati is a market leader in extrusion technology that develops, designs, manufactures and distributes innovative, high quality extruders and extrusion equipment. Continue reading “Technology Partnering with battenfeld cincinnati, austria”

The research – Recycled polymer composites

The research has great relevance given that disposal of plastic waste by way of landfills induces environmental and space problems while incineration leads to air pollution and aggravation of global warming

By Bonnie James/Deputy News Editor/Gulf Times Continue reading “The research – Recycled polymer composites”

Wood Plastic Composites to grow well through 2011

Source – Plastemart.com

Wood Plastic Composites (WPCs) are defined as composite materials that contain thermoplastics and wood in various forms. Mostly, either the polymer or the fiber, or both, can come from recycled materials. Because of the limited thermal stability of wood, only plastics that can be processed at temperatures below 392 degrees Fahrenheit are used in WPCs. The average product carries about 50% wood, generally in particulate form, such as wood flour or very short fibers. Continue reading “Wood Plastic Composites to grow well through 2011”

Wood-plastic composite used for new spirit level

David Vink, European Plastics News

Germany-based Bayerische Maßindustrie (BMI) is using profiles made by NaturinForm, a wood-plastic composite (WPC) profile producer also based in Germany, for its Polywood spirit level – the first housed in WPC. Continue reading “Wood-plastic composite used for new spirit level”

WPC – A fastest running product

Lakda Udyog Darshan, October 2011, India.

‘WPC boards’ – a fastest running product for Indian, Arab and African Infrastructure markets

– By Hardik Panchal, Hardy Smith, India (info@hardysmith.org)

Changing product trend as per the cyclic process of product life cycle, WPC boards are replacing shuttering ply boards with its enduring and highly competitive properties. Continue reading “WPC – A fastest running product”

WPC – A Future product

India’s WPC Capacity today

WPC market has actually evolved with really a good pace. In these four years, India has witnessed establishment of more than 50 odd manufacturing facilities for making different WPC products including WPC Sheets and WPC Decking. More players are in pipe line and Continue reading “WPC – A Future product”

WPC – A promising Green material

WPC – Wood Plastic Composite – a promising and sustainable green material

Hardik Panchal for Wood News, India.

WPC – Wood Plastic Composite – a promising and sustainable green material is being evolved as a fundamental product for India, after being well adopted by the world. Continue reading “WPC – A promising Green material”

WPC & HARDY SMITH

Lakda Udyog Darshan, July 2013, India.

Q1: Why wood polymer composite (WPC) is becoming more and more important for India, even though import of wood is increasing day by day?

A1: Wood plastic composite manufacturing doesn’t need logs or timbers, but this subject is a boon for wood wastes including sawmill dust, plywood sanding dust, Continue reading “WPC & HARDY SMITH”

WPC becoming popular amongst Resellers

WPC – Becoming popular amongst Re-sellers and End users

Wood polymer composite and India both are becoming popular for each other nowadays. India, as a country is becoming popular destination for PVC based WPC board’s supply. Country is set with more than 35 odd manufacturing lines for WPVC sheet lines and more than 10 lines for profile production. Continue reading “WPC becoming popular amongst Resellers”

WPC Boards – Replacing Plywood in furniture applications

WPC PVC foam sheets –Replacing Plywood, MDF & Natural wood in furniture applications

Interestingly, WPVC foam sheets are started being used in several new applications in the market. Since its inception in the Indian market PVC foam sheets have been the product of curiosity and questions. Continue reading “WPC Boards – Replacing Plywood in furniture applications”

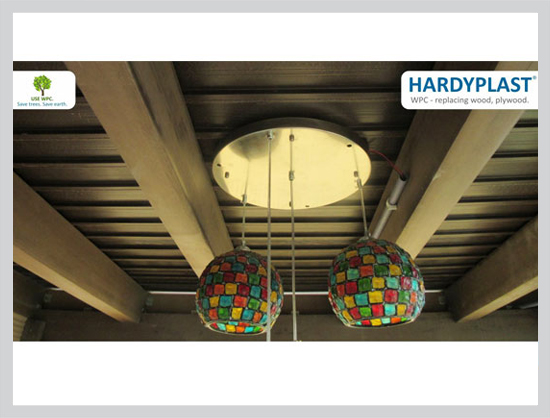

WPC Boards for Modular Kitchens

Best practices witnessed in last years for modular kitchen manufacturing is with MDF or Plywood panels because of its engineered structure and dimensions. These panels are in practice to be used with mandatory laminations of HPL/Paint on front and back surfaces. This is not only for decoration but also to protect the wooden material from moisture and termite. For high end applications PU laminations are in practice. But the basic structure of the panel is still wood and cannot be considered 100% water proof or termite proof. Continue reading “WPC Boards for Modular Kitchens”