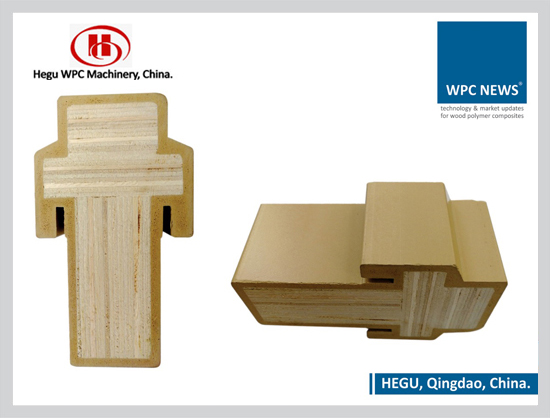

Being a professional manufacturer of WPC machines from China, HEGU from Qingdao is launching low cost and high quality WPC+LVL (Laminated Veneer Lumber) door frames by Co-extrusion technology. It is claimed to be a more stable product than solid WPC Door frames by HEGU. A few characteristics of Solid WPC Door frames like heavy weight and higher cost can be controlled with this WPC LVL technology.

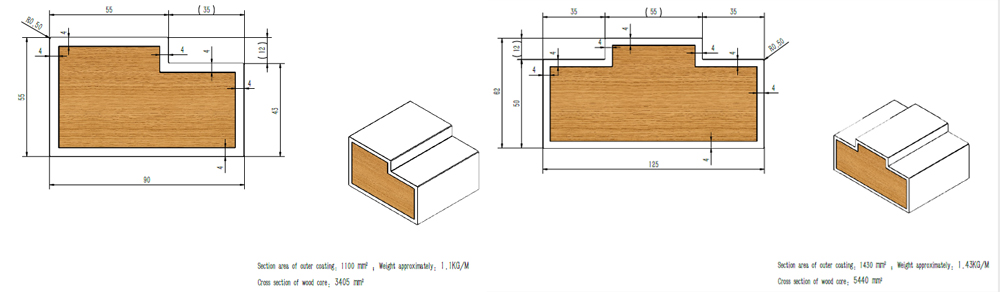

As informed by company, the inner core of the profile can be LVL wooden, MDF profile, Aluminum Profile or a steel post and the outer layer can be WPC or uPVC with 4-5mm thickness, as shown in the schematic diagram here.

Solid WPC door frames during the extrusion process foams from inside, which becomes difficult to control sometimes. In case of WPC+LVL door frame the inner core size is fixed and it is fed continuously to the extrusion. It becomes easy for machine operators to control the product quality and overall dimension. Also the 4-5mm outer WPC layer becomes easy to be controlled by the die and calibrators. So the production defective rate remains very low.

For the Solid WPC door frame cooling is very important and difficult as well from inside. Even if you increase the length of a calibrator and water tank you have to maintain the production speed at a limit of 0.3-0.5 mtr/min because of the higher thickness of the profile and higher temperature inside the product. If temperature is not controlled effectively, chances of product deformation remains after production.

For the WPC+LVL door frame, the inner is LVL core which remains at normal temperature and shall only need to be heated at the surface before feeding to the extrusion line. WPC layer is of only 4-5mm thickness, so the complete product can be easily cooled down by the calibrators and the water tank. In this case production speed also can be maintained at 0.5-0.8m/min, without product deformation.

Solid WPC Door frame is purely a Polymer foam with wood content, thus product of low density can face problem of screw holding. For the WPC+LVL door frame, the inner is high density Laminated Veneer Lumber which has advantage of high strength, high toughness, and resistant of fatigue failure caused by periodic stress and thus high nail/screw holding strength.

For more details Ms Rosy Qin can be contacted on rosy@wpcmachinery.com or Mobile/Whatsapp/ wechat: 0086-15965573925.